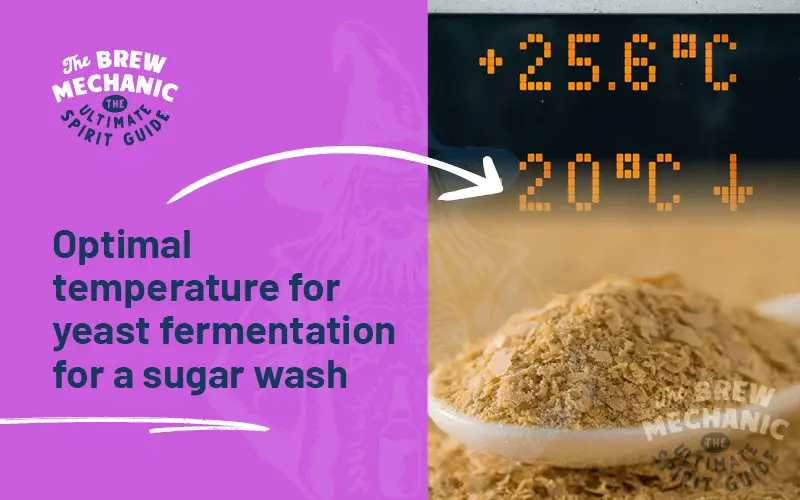

Optimal temperature for yeast fermentation for a sugar wash

Disclaimer: This post might include affiliate links, through which I may earn a small commission without any extra cost to you. Additionally, I am an Amazon Associate and earn from eligible purchases. All the products and services I suggest are ones I have personally used or would use. Thank you very much for your support if you decide to buy through any of my links!

Come join the Distilling Squad!

Get the best fundamental tips & tricks here. Woohoo!

Mastering the optimal temperature for yeast fermentation is key, especially focusing on sugar washes for distilling. Understanding and controlling the fermentation temperature is simple and anyone can do it.

We provide a simple breakdown of the ranges of temperature during fermentation depending on the strain used.

What is the Optimal Temperature for Yeast Fermentation?

The optimal temperature for yeast fermentation typically falls between 18°C to 28°C (64°F to 82°F). Within this range, yeast cells are most efficient at converting sugar into alcohol, leading to a faster and more complete fermentation process.

This temperature range is suitable for most yeast strains used in home distilling, including both ale and lager yeast varieties. Furthermore, read on about what temperature fluctuations can slow down the fermentation process.

| Baker’s Dried active yeast – alcohol content (10% to 13%) | 25 to 30°C (77 to 86°F) |

| Distiller’s yeast – alcohol content (10% to 13%) | 20 to 34°C (68 to 95°F) |

| Turbo Yeast variants – alcohol content (15% to 20%) | can start as high as 40°C (104°F), read the instructions as they are different |

Why Does Fermentation Temperature Matter for Yeast?

Yeast, a crucial microorganism in the fermentation process, is highly sensitive to temperature. The activity of yeast cells, including their ability to ferment sugars into ethanol and carbon dioxide, is significantly influenced by the temperature of the fermentation medium.

Understanding this relationship between temperature and yeast is key to successful distillation, as it affects not only the rate of fermentation but also the quality and flavour of the alcohol produced.

Any temperature changes will affect the yeast growth in the sugar wash batch.

How Does Temperature Affect the Fermentation Rate?

Temperature directly influences the fermentation rate. Higher temperatures within the optimal range can speed up fermentation, while lower temperatures can slow it down.

However, temperatures outside this range can lead to stalled fermentation or the production of off-flavours.

It is very important to achieve the optimal temperature for yeast fermentation based on the type of yeast used.

The Effects of High and Low Temperatures on Yeast

High temperatures can stress yeast cells, producing unwanted by-products like fusel alcohols, which can negatively impact the flavour of the distilled spirits.

Low temperatures, on the other hand, can make yeast dormant, significantly slowing down or stopping the fermentation process.

Selecting the Right Yeast Strain for Your Temperature Range

Different yeast strains have specific temperature preferences. Choosing a yeast strain that matches your ambient temperature conditions is crucial for optimal fermentation.

Some strains are more resistant to higher temperatures, while others thrive in cooler environments. Look at the effect of temperature based on what yeast is used.

Temperature Control Techniques for Consistent Fermentation

Maintaining a consistent temperature is vital for predictable fermentation results.

Troubleshooting Common Fermentation Process Issues

High temperatures can stress yeast cells, producing unwanted by-products like fusel alcohols, which can negatively impact the flavour of the distilled spirits.

Low temperatures, on the other hand, can make yeast dormant, significantly slowing down or stopping the fermentation process.

Advanced Tips for Precision Fermentation Temperature Control

Precision in temperature control can be achieved through the use of digital temperature controllers and high-quality fermentation equipment.

Another tip is not to have the sugar wash batch on a concrete floor as the temperature fluctuates. The solution is a rubber mat to keep the optimal temperature for yeast fermentation.

Monitoring and adjusting temperatures based on the specific stage of fermentation can optimise yeast performance, leading to a more controlled fermentation process and potentially superior quality spirits.

Last Updated on Jan 06, 2024 by The Brew Mechanic

Disclosure: I may receive affiliate compensation for some of the links below at no cost to you if you decide to purchase a product or service. You can read our affiliate disclosure in our privacy policy. The information provided is for entertainment only.

With 35 years of knowledge of being a chemical engineer in alcohol manufacturing plants, my mission is to teach the next generation of home distilling alcohol brewers at a supernatural speed.

My reviews are based on real-life experiences with reflux stills, sugar wash, troubleshooting and mystical chemical reactions.